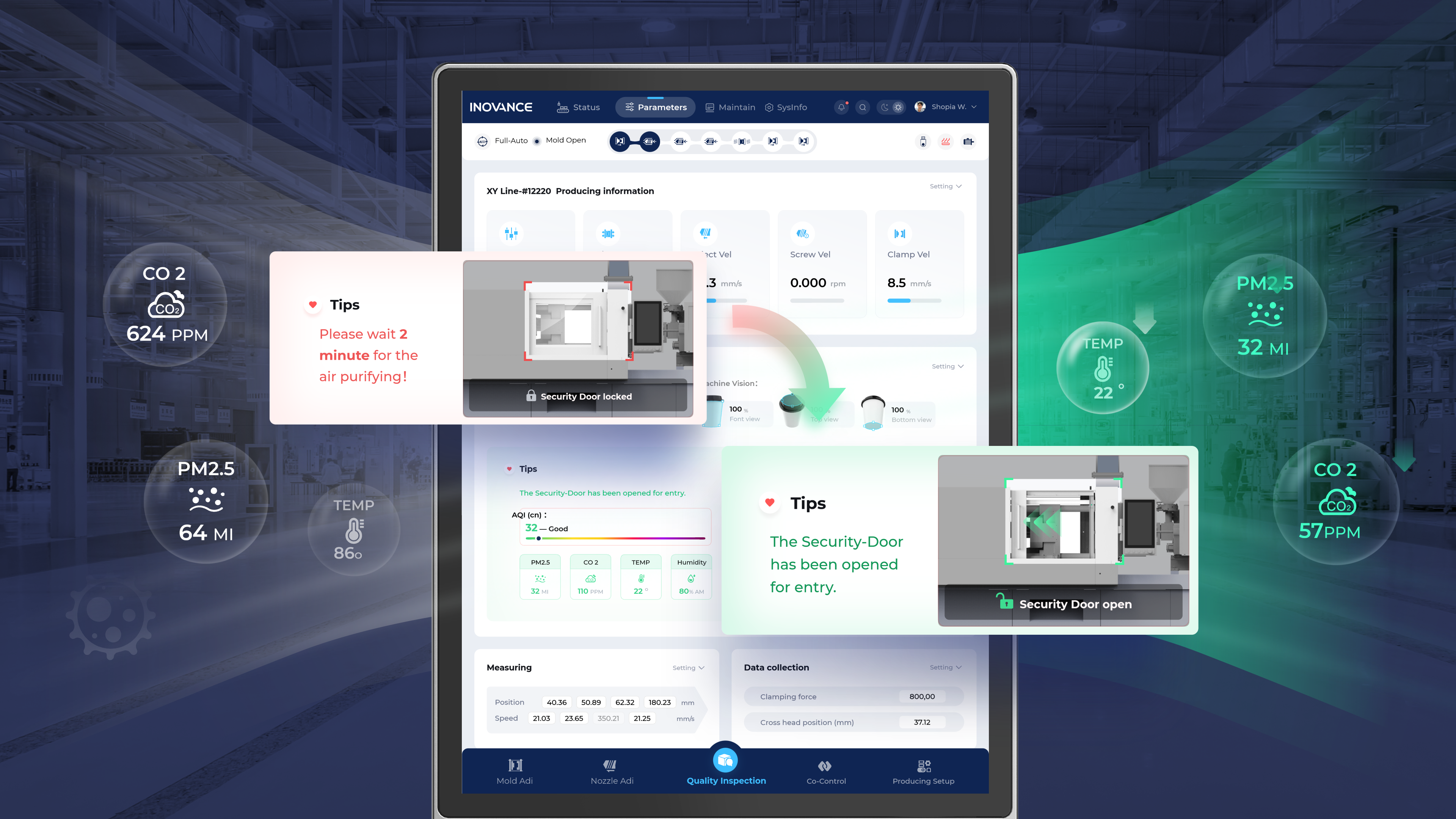

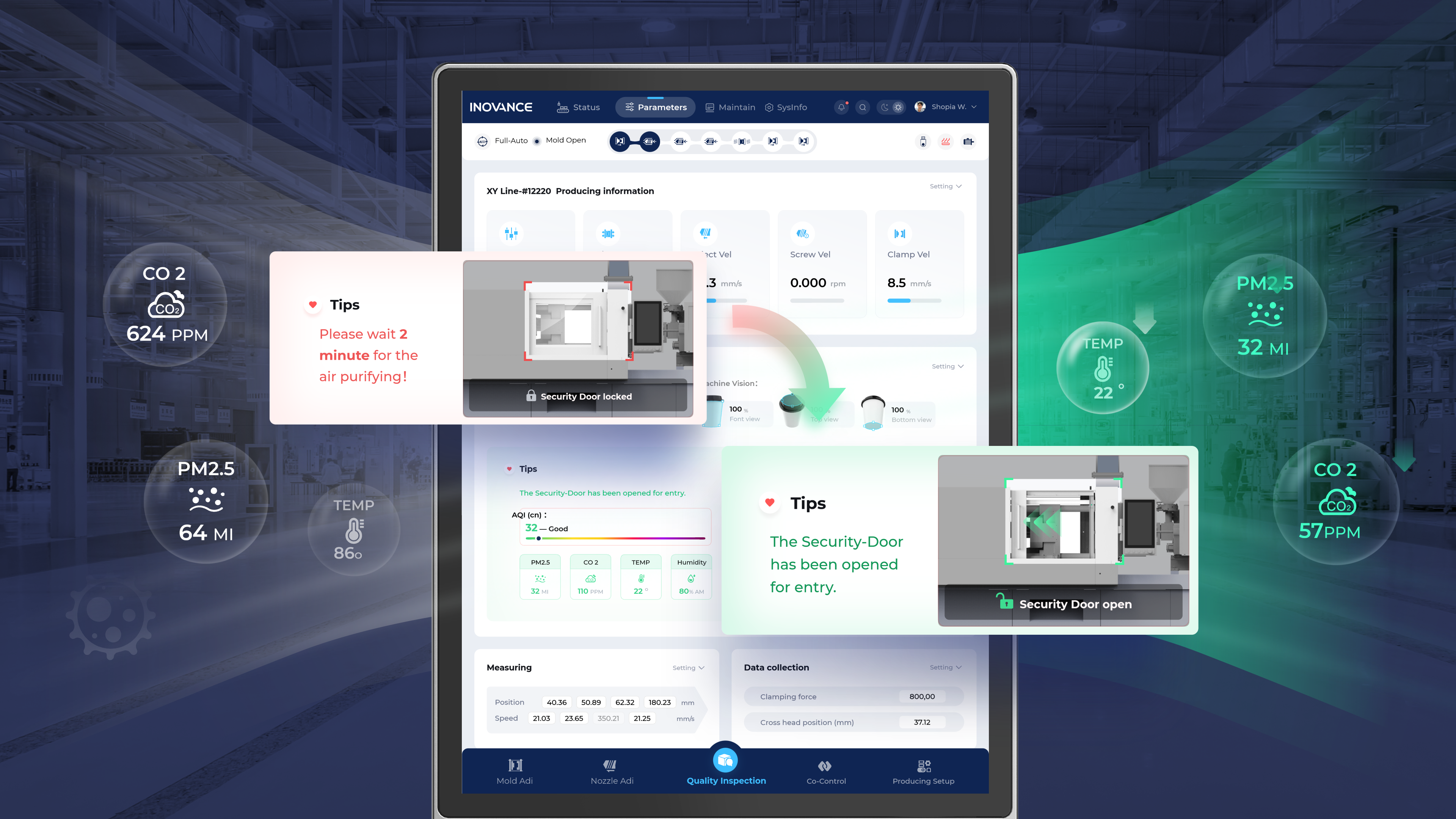

INO-IMCS Injection Moulding Control System

Service for Injection moulding manufacture

Shenzhen Inovance Technology Co., Ltd.INO-IMCS reduces plastic wasting generation for sustainable production through intelligent management of injection molding production and energy consumption. We have designed a multi-functional terminal called"InoPad", which can control all machines and auxiliary devices by one person on one terminal. Meanwhile, we combine the control system with Cloud computing and AI to ensure success on one go through simulation that reduce the waste rate from 20% to 5%. In this way, the traditional control mode was replaced by a relaxed, efficient, safety and low waste rate operation way without repetitive and error prone.

Client / ManufacturerDesign

Shenzhen Inovance Technology Co., Ltd.

Shenzhen, CNShenzhen Inovance Technology Co., Ltd.

Shenzhen, CNKui Tang,Jinxin Yang,Mengxin Li,Jia Guo,Lei Pan,Xiuting Yang,Rui Lin,Hanzhang Chen,Pei Lin,Ying Zhao,Taiyang Xiong,Zengyu Lai,Mengyuan ZhouShenzhen Inovance Technology Co., Ltd.

Shenzhen, CNZhonglin Hu,Mengying Zeng, Xinyu Liu, Yuying Xian, Xiaoxiao Pei, Yu Li, Jianjun Chen, Baoju Ding, Zhifeng Luo, Yijie HuangDate of Launch

2024

Development Time

Confidential

Target Regions

Asia

Target Groups

Trade / Industry, "Factory / Manufactory"